Industrial collaborations

Mathematical modeling and advanced algorithmic techniques become increasingly important in an increasing range of industrial applications. They are the backbone of many decision support systems or automations that require obtaining fast and near-optimal solutions to non-trivial computational problems.

Not surprisingly, many research activities and collaborations in our group are highly interdisciplinary. These range from collaborations with various other academic fields to industrial partnerships on complex real-world problems for which strong off-the-shelf solutions are not available. Moreover, the Zenklusen group is also involved in ETH's AI Center, which is the main central entity at ETH Zurich for AI related research, and fosters projects and collaborations on the understanding of the growing complexity and interdependence of modern systems.

In the following, to exemplify our interdisciplinary activities, we provide a very brief overview of some recent collaborations with the industry in our group.

Examples of industrial collaborations

IFOR promotes and values industrial collaborations, not only to facilitate knowledge transfer from theory to practice, but also to benefit from the expertise of practitioners to identify and investigate computational problems of emerging practical relevance. If your company has a challenging optimization problem arising from an industrial application, we are happy to get in touch with you to discuss a potential partnership. Over the years, IFOR has cooperated with many industrial partners from different fields, addressing a wide range of problems.

Optimization of engine maneuvers

In a collaboration with BLS Cargo, we optimize maneuvers of train engines on storage tracks. Due to a variety of requirements, depending on the trajectory and train composition, different numbers and types of engines are required. For example, before a cargo train enters a segment of a trajectory with high slope, additional engines are often necessary. The ability to add and remove engines at crucial points on the train network is key to avoid an excessive overuse of engines. BLS Cargo therefore maintains storage tracks for engines. Train maneuvers to properly place engines on storage tracks and to pull the correct engine type from a storage track can require significant time, and delays can quickly propagate into global operations of BLS Cargo. Ideally, the goal is to place and pull engines onto/from the storage tracks in a way that only requires simple and fast maneuvers. In particular, a typical situation to be avoided to the extent possible, is that an engine has to be moved out of the storage tracks that is buried behind other engines that need to be moved first. This leads to additional engine maneuvers requiring substantial time on the side of the BLS Cargo train drivers. Different sources of uncertainty regarding the arrival and departure times of trains make the optimization of train maneuvers on storage tracks a highly non-trivial task, for which we develop decision support software based on mathematical optimization techniques.

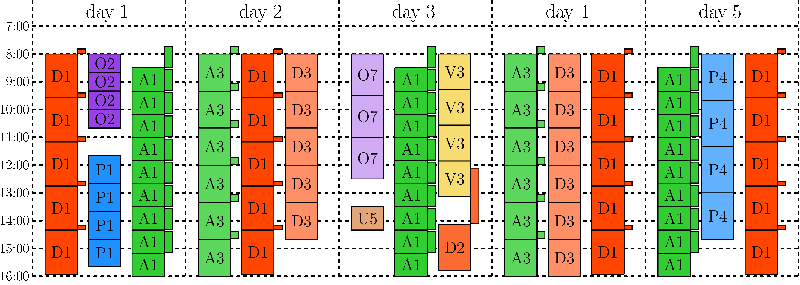

Scheduling of operating rooms

We supported the University Hospital of Zurich on a variety of questions around the scheduling of operating rooms. This includes planning problems around the operation of a new center at The Circle, a new complex of building next the airport of Zurich. The scheduling of operating rooms is a highly non-trivial task subject to a multitude of requirements and sources of uncertainty. We developed algorithmic decision support tools that allow for optimizing various aspects of the scheduling process.

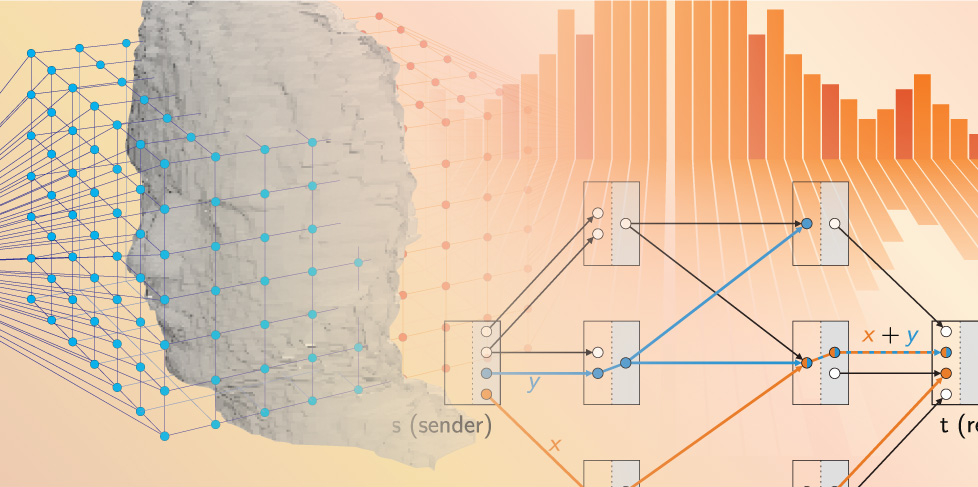

Rolling stock scheduling

The dense and highly efficient Swiss railway system is a key element of the Swiss mobility landscape. The Swiss Federal Railways (SBB) operate a large fleet of rolling stock vehicles to meet an increasing demand. To ensure that the trains run on time and that passengers can rely on the service, the SBB must carefully plan the schedules of its rolling stock. This involves, among many other things, determining which trains with how many coaches should run on which routes, planning regular maintenance slots, and minimizing deadhead trips (trips without passengers). How can advanced optimization algorithms help to design highly efficient rolling stock schedules for the Swiss train system of the future? To explore this question, we collaborated with the Swiss Federal Railways (SBB) on a joint research project that was supported by Innosuisse.